In the project design, first of all, electrical projects are prepared for application in the site, EPLAN drawings and necessary documents are prepared precisely and directed to implementation. During the design phase, the electrical project is prepared in EPlan format and material list, cable list, terminal diagram, panel dimensioning and other documents are generated from the same program in the EPlan program.

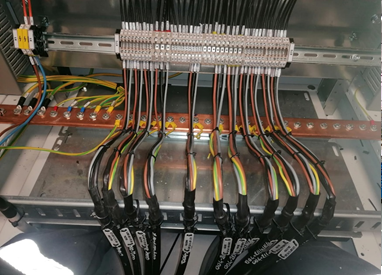

All our LV panels are designed and made in accordance with 2D, 3D form. Our LV panels are manufactured using Siemens, Schneider, ABB switchgear materials in accordance with 2d and 3d forms, ergonomic and usable. Panel productions are passed through detailed testing phase without going to the site for electrical project compliance.